| For Ray-Lin Index, click HERE ***** To return to the BCOIE Chapter website click HERE or on our logo above. |

|

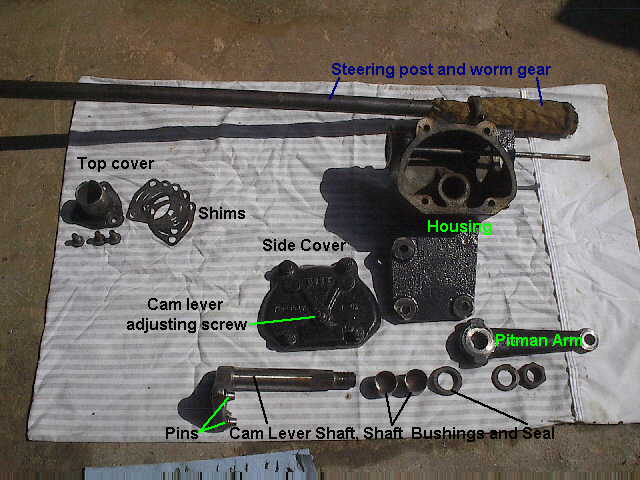

1955 Studebaker Ross Steering Box Rebuild Even though this technical page specifically targets a 1955 Studebaker President sedan, the procedure is basically the same for all Ross Steering box equipped Studebakers. Symptoms:

Procedure: When no amount of adjustment to the Cam-Lever (pitman) Shaft adjustment screw corrects a loose steering situation, It's a pretty safe bet that the steering box is worn beyond repair. The first thing to do is remove the horn button, horn ring, and then the steering wheel using an appropriate puller. Remove any wiring going to the turn signal switch and into the steering column. On later cars- the neutral safety switch is also located on the end of the column near the firewall- that will need removed also remove the bolts that hold the steering post jacket bracket to the main dash brace. Remove the 4 phillips screws holding the rubber steering column dust shield. Moving to the engine compartment - remove the shifter linkages, and loosen the steering post jacket clamp, remove the left front wheel, unplug the horn wire if so equipped. On some cars- you may need to remove such items as: the battery box, starter, and/or the left exhaust manifold, in order to have room to get the steering column out through the wheelwell of the car Remove the reach rod from the end of the pitman arm, and/or remove the pitman arm if (easily) possible at this time. This will depend on how tight it is, and how much room you have to work. Remove the 3 bolts holding the steering box to the vehicle frame. It's a good idea to have a helper inside the car- to keep the column from flopping around and possibly getting the seat dirty or tearing it. The column should drop away from the dashboard. On the '55, I was able to twist the steering box over the front suspension- and pull the steering post out of the post jacket. This allowed the entire unit to be pulled out through the fenderwell. On a Hawk I have done before, I had to drop the steering box straight out the bottom of the car. (click images to enlarge) 9. Once the column is out, you need to put it in a vice to continue the dismantling. 10. Remove the Pitman arm using a good quality puller. Leave the retaining nut on the end of the cam lever shaft- to help prevent damage to the threads. 11. Next, loosen the cam lever shaft adjustment screw locknut- and remove the adjustment screw. Remove the side cover. Studebaker used a lightweight gear oil in their steering boxes. It should be quite gooey if it's never been changed. Use a small plastic 1 pint tub to catch any grease or oil that comes out. Once the cover is off- and the oil drained- pull the cam lever shaft out of the housing. You can use a rubber or leather mallet, or hammer and block of wood to drive it out if necessary. 12. Remove the (3) or (4) bolts that hold the housing top cover (the shaft goes through here). This cover will have several shims- used to adjust the clearance of the steering post's bearings. There may even be a brass gasket. Slide the top cover, shims and gaskets off of the steering post, and remove the steering post and worm gear. On some models, the bearings will come out with the worm gear as an assembly. You can see in the picture below right- there is a small tube through the housing. This tube is for the horn wire to run through. It is pretty fragile- and can be bent easily. 13. Use a dull punch or chisel to drive the (2) bushings and (1) seal out of the cam lever shaft housing. The bushings are soft and have a slot in them, so they are easily removed. DO NOT plan on saving them- you will never get them out without damage. 14. Clean all parts, inspect the cam lever shaft's PIN/PINS for wear. If you notice flatspots, the shaft or pin/pins need to be replaced. Later Ross boxes used a single PIN mounted inside tapered roller bearings. Often this pin will freeze up and wear. This assembly is available, and replacing it is not too difficult. This saves you from having to replace the whole cam lever shaft. 15. Reassembly is the reverse of the above procedure. It is very easy to damage the new bushings trying to put them back in without a proper bushing driver. When reinstalling the steering post and worm gear, do not tighten the top cover bolts unless you have the proper endplay set by using the shims.

|

|

www.StudebakerSoCal.com |